Ready to launch your own podcast? Book a strategy call.

Frontlines.io | Where B2B Founders Talk GTM.

Strategic Communications Advisory For Visionary Founders

Conversation

Highlights

A bug crawled into a valve seeking warmth during a cold snap in January 2025. It died there, teaching XL Batteries a lesson no laboratory could provide: real-world deployment reveals challenges you can’t anticipate in controlled environments.

This happened on the day XL Batteries shipped their first commercial unit to Houston – a milestone four years in the making. The journey to this point offers critical lessons for deep tech founders about scaling hardware innovations.

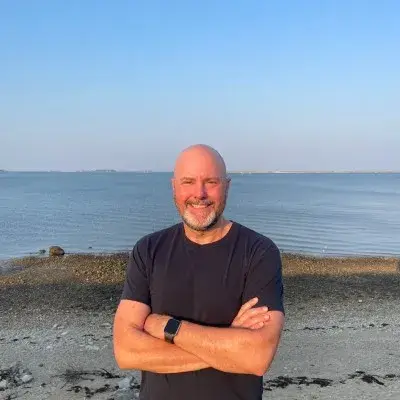

In a recent episode of Category Visionaries, CEO Thomas Sisto shared insights from building a company that’s raised $20 million to tackle one of energy’s most pressing challenges: grid-scale storage.

The $4 Trillion Technical Problem

Most massive markets get solved quickly because the incentives are irresistible. But grid-scale energy storage remains an exception. As Thomas explains, “It’s an unsolved problem. It’s a $4 trillion market with a T… There are not a lot of markets that are that big because people solve those problems. It’s an unsolved problem because it’s a technical problem.”

This insight shaped XL Batteries’ entire approach. While many startups focus on business model innovation or supply chain optimization, XL Batteries recognized they needed to solve fundamental chemistry challenges first.

The breakthrough came during Thomas’s postdoctoral research at Columbia University. His team discovered organic molecules derived from oil and gas that could charge and discharge without degrading. This opened the possibility of batteries lasting 50+ years – a game-changer for utility-scale storage.

Don’t Reinvent the Wheel

Instead of developing entirely new battery architecture, XL Batteries made a crucial strategic decision: innovate within proven frameworks. “We haven’t invented a new mousetrap,” Thomas explains. “It’s an old mousetrap. The key for us is to just really drive cost out of it.”

They built on NASA’s flow battery design from the 1980s, which uses vanadium dissolved in sulfuric acid. XL Batteries replaced these expensive, corrosive materials with organic molecules in pH-neutral saltwater. This approach allowed them to leverage existing engineering while dramatically reducing costs.

This strategy extends beyond the core technology. When building their team, they recruited veterans who had scaled similar technologies. Their chief commercialization officer was the co-founder and CTO of A123 Systems, which had the largest battery IPO in 2009. They also brought in Pfizer’s executive vice president of global chemical manufacturing to apply pharma industry expertise to chemical production.

The Power of Field Data

The journey from laboratory to commercial deployment revealed a critical principle: field testing provides irreplaceable insights. “It’s nothing like field data,” Thomas emphasizes. “You learn so much from being in the field. It’s so different from a laboratory environment.”

This isn’t just about finding bugs in valves. It’s about understanding how your technology behaves in real-world conditions, dealing with unexpected environmental factors, and discovering maintenance challenges you couldn’t anticipate in the lab.

Marketing in Deep Tech

XL Batteries’ approach to marketing offers another valuable lesson. While many startups rush to build market presence, they’ve been deliberately patient. “We have not invested in marketing at this point,” Thomas notes. “We’re getting into sort of a stone’s throw offering commercial product.”

This restraint reflects a deep understanding of their market. Unlike consumer products where brand excitement can drive sales, utility infrastructure demands proven reliability and compelling economics. As Thomas explains, “Energy and electricity is hidden… you just want your lights to work and you don’t want to pay more than whatever it happens to be 15 cents per kilowatt hour.”

The Vision Ahead

XL Batteries aims to enable a fundamental transformation of energy infrastructure. Their technology can store energy for 12-100 hours, far exceeding lithium batteries’ eight-hour limit. This capability is crucial for managing intermittent renewable energy sources like solar and wind.

“Fundamentally we want to change the way society operates in the exact same way that oil and gas has changed the way society operates,” Thomas shares. It’s an audacious vision, but one grounded in solving real technical challenges rather than just painting an attractive future.

The Path Forward

As XL Batteries moves from successful demonstration to commercial scaling, their journey offers valuable insights for deep tech founders:

- Focus on solving technical problems when they’re truly the barrier to market adoption

- Build on proven architectures instead of reinventing everything

- Recruit team members who have scaled similar technologies

- Let field data drive development

- Time market education based on product readiness, not market hype

These principles have helped XL Batteries progress from a laboratory discovery to shipping their first commercial unit. The next chapter of their story – scaling to utility-grade deployment – will test these principles in new ways.

Actionable

Takeaways

Build an elite technical team early:

Thomas emphasized the importance of bringing in experienced leaders from successful companies in adjacent spaces. He recruited the co-founder/CTO of A123 Systems (largest battery IPO of 2009) as chief commercialization officer and executives from Pfizer and Plug Power. This mix of startup scaling experience and deep technical expertise helped them avoid costly mistakes and technical debt.

Start with proven architectures:

Rather than inventing entirely new systems, XL Batteries focused on innovating within established frameworks. They used the proven flow battery architecture but replaced expensive vanadium/sulfuric acid with organic molecules in saltwater. Thomas explained, "We haven't invented a new mousetrap. It's an old mousetrap. The key for us is to just really drive cost out of it."

Focus relentlessly on cost in utility markets:

Thomas highlighted that unlike consumer products where premium pricing can work, utility products must prioritize cost and reliability above all else. "Energy and electricity is hidden... you just want your lights to work and you don't want to pay more than 15 cents per kilowatt hour." This drives every product design decision.

Leverage existing industry infrastructure:

By using organic molecules from oil and gas feedstocks, XL Batteries tapped into established supply chains and manufacturing capabilities. This reduced scaling risk compared to approaches requiring entirely new manufacturing processes or rare materials.

Time market entry carefully:

Despite having revolutionary technology, XL Batteries waited until they had a fully integrated demonstration unit before pursuing major marketing efforts. Thomas noted they're only now approaching the "tipping point" for marketing as they near commercial product availability.